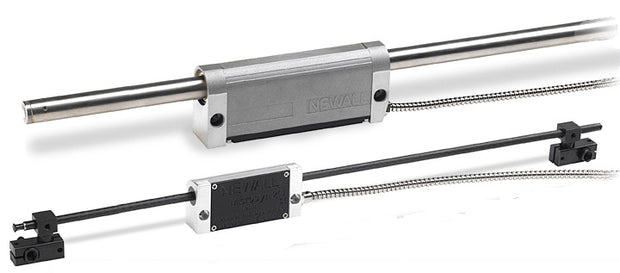

Microsyn 5 Encoder

- IP67 (NEMA 6)

- Withstands dust, dirt, oil and other environmental conditions

- No mechanical wear characteristics

- Requires no cleaning or maintenance

- High tolerance to shock and vibration

Consistent accuracy and reliability even under the most extreme shop conditions

Designed to work exclusively with Newall's digital readouts, the Microsyn™ encoders embody a truly innovative design in which all of the electronics and measuring components are sealed and protected. The encoders carry an IP67 environmental rating and will continue to provide accurate, reliable readings even when fully submerged in water, oil or coolant. No other linear encoder matches the durability and reliability of Newall's reader heads and scales.

Standard travel lengths up to 11 meters.

Environmental Protection

All variants of Newall linear encoders carry an Ingress Protection (IP) rating of 67 (IEC 529). The encoders are fully submersible and will continue to provide accurate and dependable readings under the harshest conditions. Dirt, swarf, cast iron dust, graphite dust and other common contaminants will not affect the performance of the linear encoder system.

Accuracy, Repeatability, and Resolution

The laser measurement system used to calibrate all of Newall scales have been calibrated by accredited laboratories providing traceability to UK national standards. The procedures comply with the requirements of British Standard Specification BS5781/International Standard ISO10012-1. The National Physical Laboratory (NPL) calibrates the master standard, certificate number 08A014/9501. All Newall Calibration rigs are traceable back to this NPL standard. The calibration of the Newall scales and reader heads is conducted in a temperature controlled 69.8°F (21°C) environment.

Shock and Vibration

In comparison to other linear displacement technologies, Newall's linear encoders are tolerant to high degrees of vibration and shock.

- Shock and Impact (11ms IEC 69-2-6):

Spherosyn™ technology = 1000m/s2 (100g) - Vibration (55 - 2000Hz IEC 68-2-27):

Spherosyn™ technology = 300m/s2 (30g)

Newall linear encoders will not skip count even at high traverse rates. Travel rates of up to 2 meters per second can be achieved, while the Absolute encoder version carries a slew rate of up to 196.85’ (60m)/second.

Reliability

Newall linear encoders require no regular cleaning or maintenance, unlike non-contact systems; the linear encoders have no general wear characteristics. There are no LEDs to burn out or glass scales to get scratched or broken. There are no roller bearings, leaf springs or other moving parts to wear out or fail.

Ease of Installation

Installation is simple and forgiving and can be accomplished in a fraction of the time as compared to other linear encoder systems. Even with scale lengths up to 36’ (11m), machined surfaces or backing bars are not needed. For more compact installations, scales less than 20” (508mm) in length need only be supported on one end of the scale. Unlike tape-based systems, they do not rely on a head-to-tape gap height that can vary due to pitch, roll, and yaw of a machine’s traveling axis.

Thermal Expansion

The thermal behavior of the linear encoder is an essential criterion for the working accuracy of a machine tool. And thus it is common knowledge that the thermal behavior of the linear encoder should match that of the workpiece. Newall encoders carry a coefficient of thermal expansion of 12ppm, the same as steel/iron.

In comparison to glass based encoders, a 50°F (10°C) temperature rise can result in a thermal expansion error in the order of 0.0016" (40μm) over 39.4" (1m) of travel. Newall encoders will expand and contract at the same rate as the machine tool and machined part resulting in better accuracy performance.